In relation to modern producing and design, laser cutting know-how stands out as being a activity-changer. Think about with the ability to Reduce by elements Using the precision of the surgeon as well as pace of the racing automobile—that’s the magic of a laser cutting device. No matter if you are involved with a DIY challenge or jogging a significant-scale industrial Procedure, knowledge laser cutters is essential.

So, what exactly is often a laser cutter? Primarily, it’s a device that employs a laser beam to chop supplies with remarkable precision. It’s like having a significant-tech blade that by no means dulls. This technological know-how has revolutionized industries by providing superior precision and effectiveness. Consider it as a super-charged Variation of All those outdated-faculty slicing resources, but with lasers instead of metallic blades.

Some Known Details About Laser Cutting Systems

Industrial laser chopping is a significant process in several sectors, from automotive to aerospace. It’s not pretty much slicing; It is really about acquiring unparalleled precision. Whenever you will need sections with correct measurements, industrial laser chopping delivers final results which can be both equally reliable and repeatable. It’s like using a learn craftsman who by no means makes faults.

Industrial laser chopping is a significant process in several sectors, from automotive to aerospace. It’s not pretty much slicing; It is really about acquiring unparalleled precision. Whenever you will need sections with correct measurements, industrial laser chopping delivers final results which can be both equally reliable and repeatable. It’s like using a learn craftsman who by no means makes faults.CNC laser slicing takes issues a stage more by integrating Personal computer Handle. CNC stands for Pc Numerical Management, which suggests which the slicing device is operated by way of a computer. This enables for complex and intricate patterns being executed flawlessly. Think about having the ability to attract some thing in your computer and then Have a very equipment generate it for yourself, down to the best details.

Laser chopping engineering is continually evolving. New enhancements are pushing the boundaries of what these devices can do. For illustration, Newer models supply Improved cutting speeds and better Power efficiency. These updates mean that businesses can make significant-good quality solutions more quickly and with a lot less waste. It’s like upgrading from the essential tool to the significant-functionality one which boosts your productivity.

Cnc Laser Cutting Can Be Fun For Everyone

Precision laser slicing is another major element of this engineering. With regards to creating elements that must match alongside one another perfectly, precision is essential. Laser cutters attain this by focusing a laser beam with pinpoint accuracy. This makes sure that every Slice is exactly wherever it should be. Think about attempting to healthy with each other puzzle pieces which are Minimize so specifically that they Virtually snap into area by by themselves.

Precision laser slicing is another major element of this engineering. With regards to creating elements that must match alongside one another perfectly, precision is essential. Laser cutters attain this by focusing a laser beam with pinpoint accuracy. This makes sure that every Slice is exactly wherever it should be. Think about attempting to healthy with each other puzzle pieces which are Minimize so specifically that they Virtually snap into area by by themselves.Laser cutting devices is on the market in a variety of configurations, tailored to various wants. Some devices are made for reducing skinny resources like paper or material, while others are constructed to manage weighty-responsibility jobs involving metal sheets. No matter if you’re dealing with delicate elements or robust metals, there’s probable a laser cutting equipment that fits the Monthly bill. It’s like getting a versatile Device that adapts to any job you throw at it.

Sheet steel laser cutters are a major illustration of specialised devices. These equipment are made to handle big sheets of steel and Slice them into intricate shapes and patterns. In case you’re within the producing field, you know how vital it's to own tools that will cope with both of those precision and scale. A sheet steel laser cutter is your go-to Resource for these types of duties, presenting performance and accuracy in equal evaluate.

Laser cutting services are an incredible choice for firms That won't provide the capital to speculate in their own laser slicing device. By outsourcing to some company company, you can get use of condition-of-the-artwork technology without the hefty value tag. These companies present the skills and gear required to tackle even probably the most challenging tasks. It’s like hiring a expert who’s already Outfitted with the ideal equipment for the career.

Laser cutting methods are made to supply a complete Option for numerous slicing desires. These units integrate the laser cutter with application and other parts to create a seamless operation. Think about it being a well-oiled device exactly where each and every part functions in harmony to make large-excellent effects. From First design and style to remaining Reduce, laser chopping methods streamline your entire process.

Among the list of main advantages of laser cutting engineering is its versatility. It’s not restricted to only one style of fabric or challenge. You can utilize laser cutters for anything from intricate jewelry types to significant-scale industrial factors. This versatility helps make laser cutting a precious Software in a variety of fields. It’s like aquiring a Swiss Army knife for slicing duties, ready to deal with what ever arrives your way.

Along with flexibility, laser slicing offers a standard of depth that’s hard to match with standard cutting strategies. The concentrated laser beam can build intricate patterns and great strains with Excellent clarity. This is especially valuable for industries that involve high amounts of element, such as the electronics or fashion industries. It’s like having a magic wand that turns your comprehensive patterns into fact.

More About Laser Cutting Equipment

Routine maintenance of laser cutting equipment is another essential element. Even though these devices are unbelievably productive, they do need frequent maintenance to be sure they continue to accomplish at their most effective. Maintaining the optics clean up as well as application updated could make an enormous change in the device’s efficiency. Visualize it as typical Test-ups for the superior-effectiveness sporting activities car to help keep it operating efficiently.When considering laser slicing devices, it’s vital to decide on a machine that matches your precise requirements. Factors like the kind of fabric, thickness, and desired Reduce excellent will all impact your conclusion. It’s like Selecting the correct Resource with the career—obtaining the correct laser cutter can make all the real difference in accomplishing the very best outcomes.

Laser chopping devices will also be a boon for prototyping. When you’re developing a different item, you could immediately build prototypes to check and refine your styles. This quick prototyping capacity speeds up the development course of action and helps you make enhancements prior to heading into whole output. It’s like aquiring a rapidly-ahead button to your style process.

Indicators on Laser Cutting Machine You Should Know

Security is a vital consideration when applying laser slicing technologies. While these machines are remarkably productive, they also require suitable security protocols to forestall accidents. This involves sporting protecting eyewear and ensuring which the workspace is perfectly-ventilated. It’s like aquiring a significant-tech Software that should be managed with treatment to obtain the greatest effects without the need of compromising protection.

The impact of laser slicing technological know-how around the natural environment is an additional aspect truly worth noting. In comparison to conventional chopping procedures, laser get started slicing usually detailed info generates less squander as a consequence of its precision. On top of that, several present day laser slicing equipment are meant to be Electrical power-economical, lowering their All round environmental footprint. It’s like possessing a chopping-edge Device that’s not merely successful but in addition eco-friendly.

Last but not least, the future of laser chopping engineering appears promising. With ongoing breakthroughs in technological know-how, we will be expecting much more progressive functions and abilities. From a lot quicker cutting speeds to Laser Cutting Technology much more Superior elements, the probable for laser slicing is broad. It’s like viewing a technology evolve into a thing far more extraordinary, growing its possibilities and purposes.

Tony Danza Then & Now!

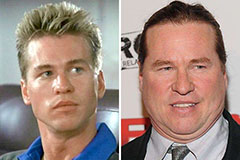

Tony Danza Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Sydney Simpson Then & Now!

Sydney Simpson Then & Now! Shane West Then & Now!

Shane West Then & Now! Melissa Sue Anderson Then & Now!

Melissa Sue Anderson Then & Now!